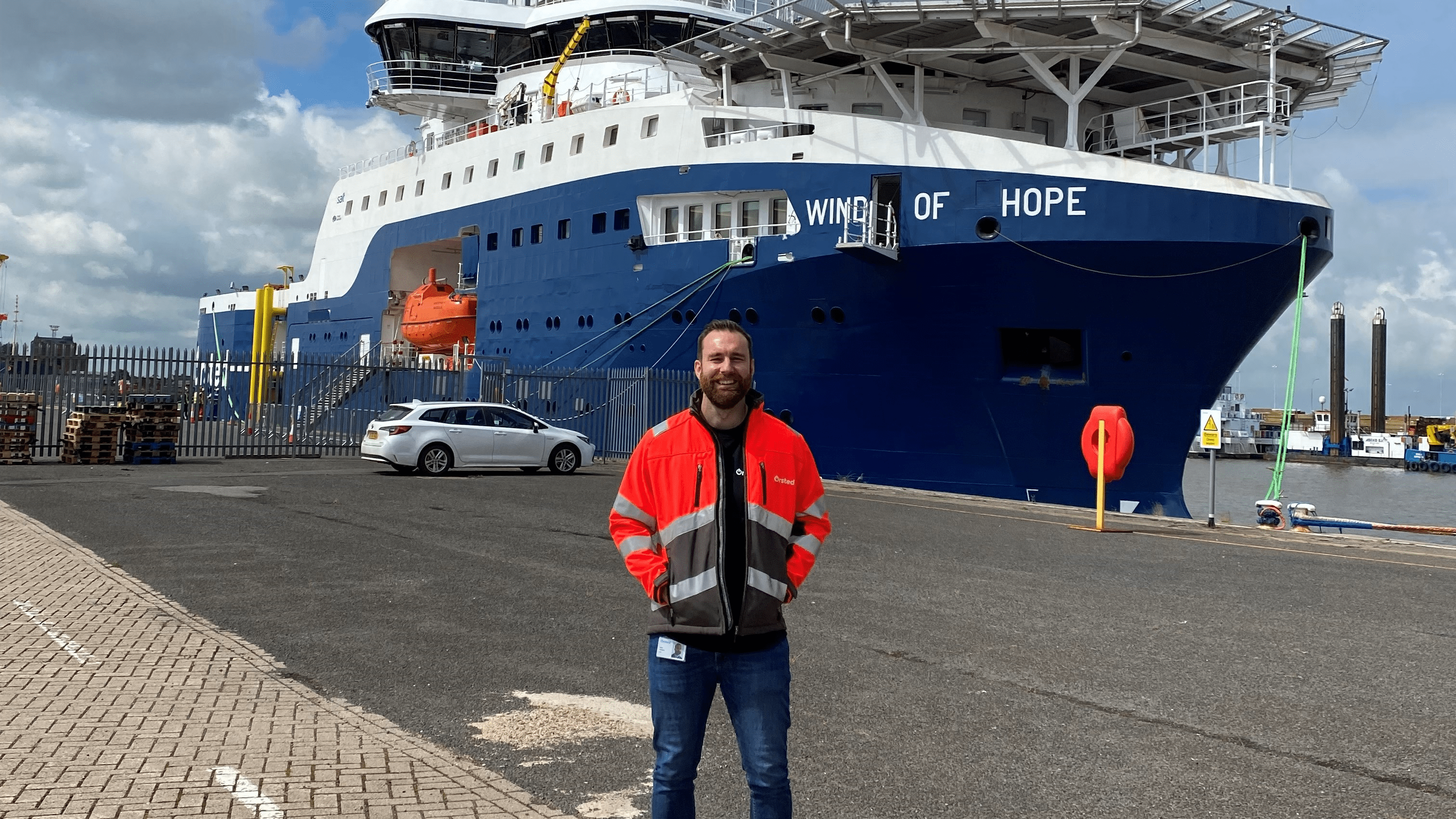

Since winning their first offshore wind contract with Ørsted back in 2017, horizontal directional drilling specialists AMS Trenchless have completely transformed their business. The highly specialised drilling company has expanded its expertise, grown its workforce, and is proud of its role in the local green energy transition.

“We’re all very positive about the future,” says Peter Guilliatt, Operations Director for AMS Trenchless.

Growing local expertise

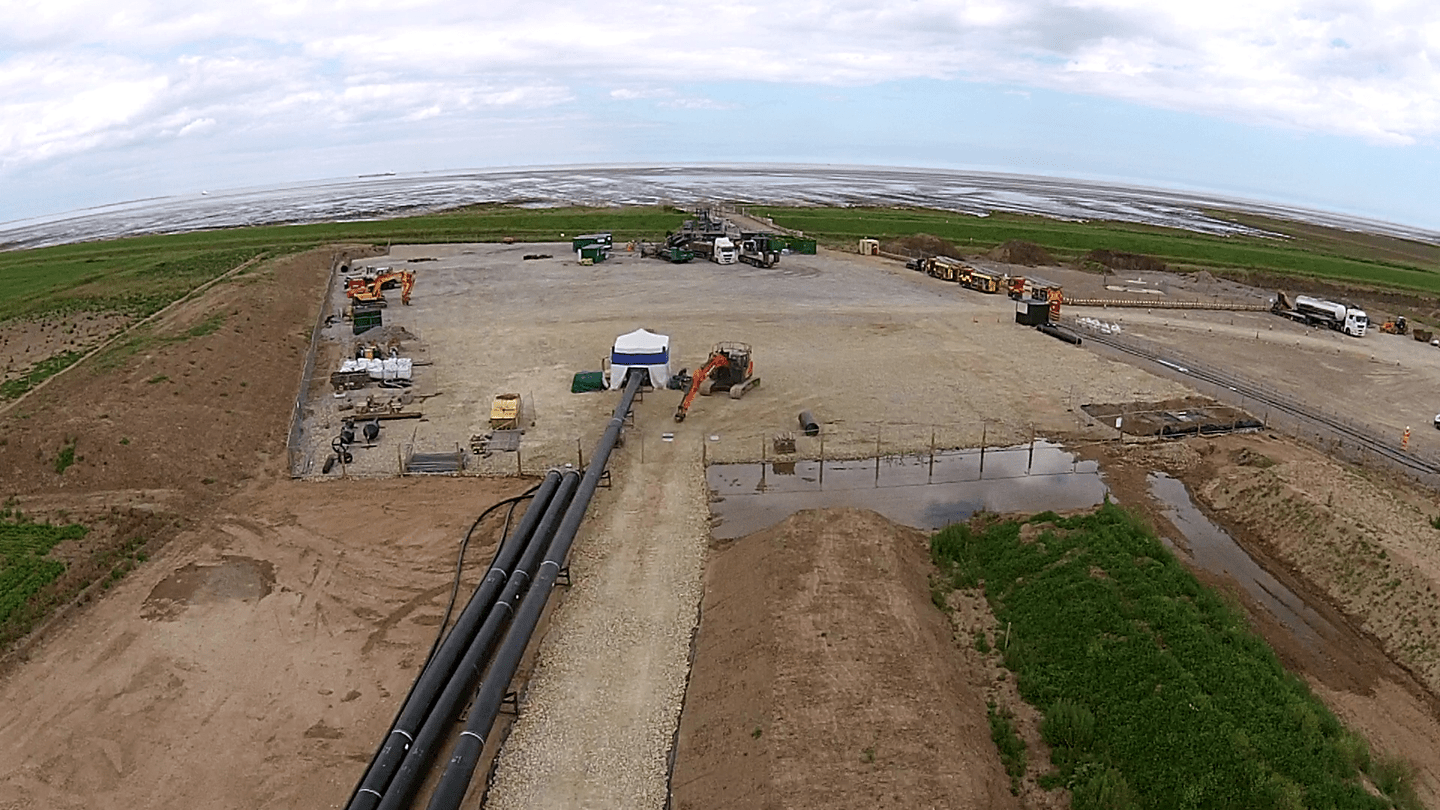

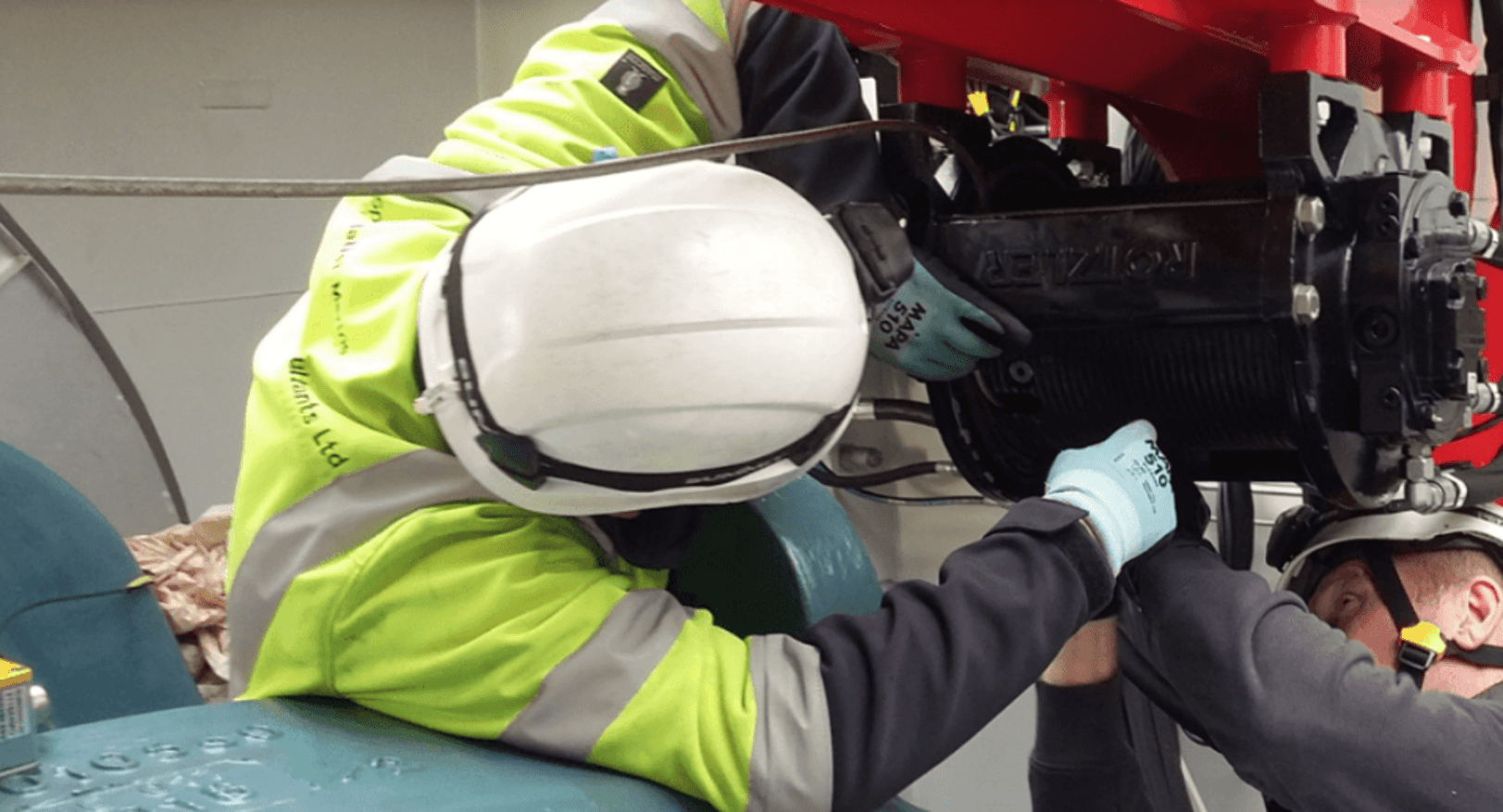

Connecting an Ørsted offshore wind farm to an onshore sub-station requires an extremely specialised set of skills. The cable needed to be pulled through underneath the sea defences without damaging them or negatively impacting local biodiversity.Even though AMS did not have previous experience with that kind of project, Ørsted initially invited the Scunthorpe-based business to tender to carry out the trenchless drilling at Hornsea 1. It was an opportunity that proved to be a watershed moment for the company’s drive, energy, and prospects.

“Ørsted quickly realised we needed a bit of help,” says George Aitkenhead, Managing Director at AMS. But he says Ørsted were willing partners who helped AMS develop and refine its expertise through its work on Hornsea 1 and Hornsea 2 – setting it up for even bigger projects.

A ‘different mindset’

Since working with Ørsted, AMS has “expanded massively,” employing lots of local talent and training new unskilled labour in-house to reach the level of expertise required for its complex work.

Working with Ørsted has paved the way for other, large-scale offshore wind contracts, completely redefining the company’s outlook.

“The energy and mood of the company has completely changed, we’re all in a different mindset, ever since Hornsea 1 and 2,” says Peter. “Ever since then, it’s escalating.”