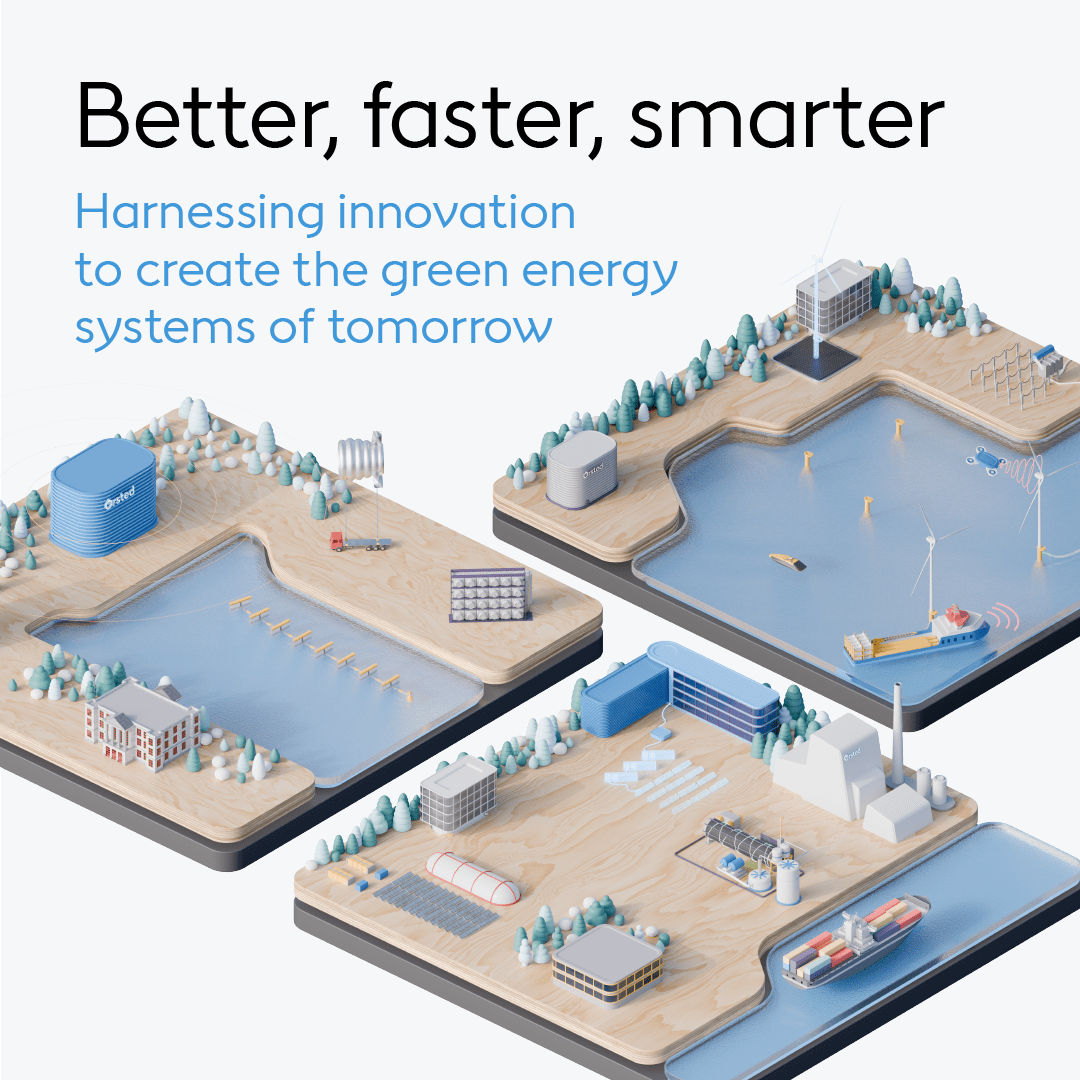

At Ørsted, innovation is core to our business.

Thanks to world-class engineering, we took offshore wind from science fiction to an energy source that’s cost-competitive with fossil fuels.

But we’re not stopping there. Our goal is to create a world that runs entirely on green energy through continued, rapid, and collaborative innovation.

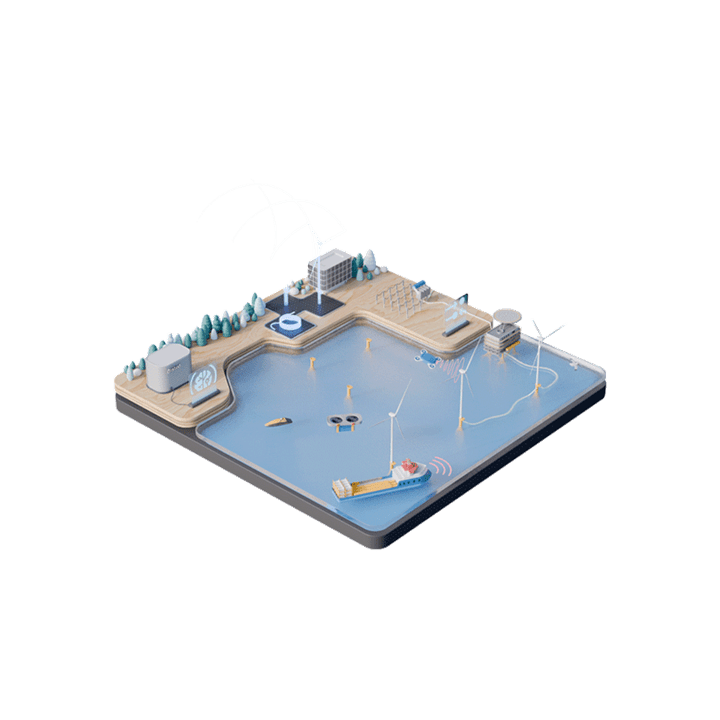

We believe we can continue to harness existing and new technologies to make green energy more affordable, reliable, efficient, and sustainable across the value chain.

But we know we can’t do it all alone. To spark the next generation of innovative ideas to speed up the global green energy build-out we seek out collaborative partnerships.

We work with other industry leaders, start-ups, the investment community, and academic institutions all over the world through our global network of Innovation Hubs. For instance, we started the UK and Ireland Innovation Hub a year ago to provide a front door for innovators looking to collaborate with a global green energy leader like us.